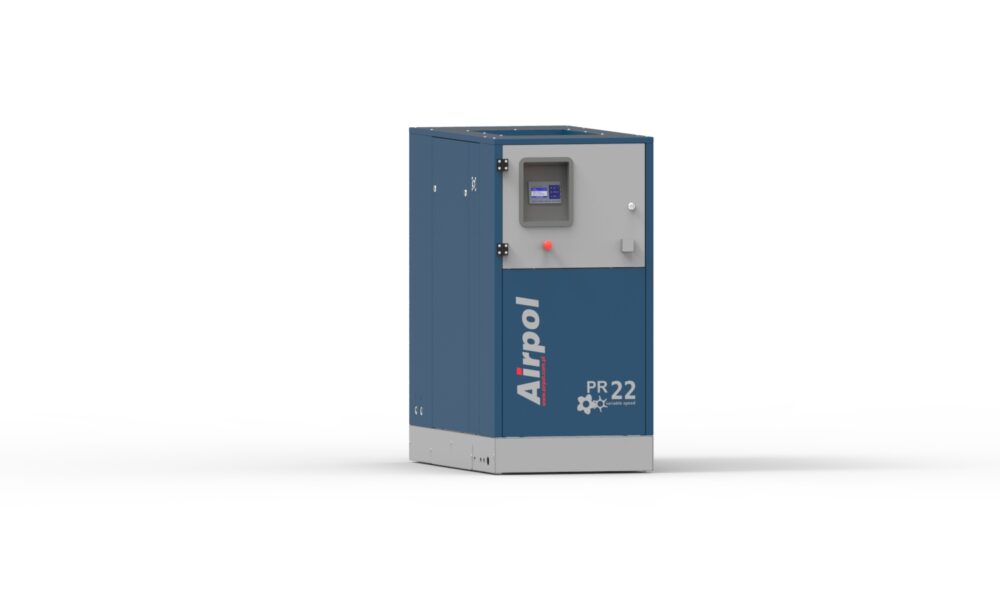

Airpol PR screw compressors equipped with a frequency converter use variable speed drive technology. Our design office specialists have designed compressors with improved energy efficiency that ensure an efficient air system and at the same time reduce energy bills. A special drive used in Airpol PR screw compressors controls compressor speed, which results in:

- smooth regulation of compressor speed within the range from 20% to 100%,

- adjustment of compressor capacity to actual consumption of compressed air,

- energy savings up to 70% in comparison to compressors with traditional control.

When the demand for compressed air is low, the motor in a variable speed drive screw compressor will run at reduced speed. This will result in lower electricity consumption. The motor frequency of the variable speed compressor will automatically increase when the demand for compressed air increases. This adaptation of compressor operation has measurable benefits in the form of lower electricity costs and less wear on compressor components, which extends compressor service life and reduces maintenance costs.

- constant network pressure at a preset value

The frequency converter control system tries to maintain the compressor motor rotation speed so that there is a constant pressure in the compressed air system at a preset value. When the network pressure decreases the inverter increases the rotational speed of the electric motor, which increases the capacity of the compressor, whereas when the pressure increases the rotational speed of the motor decreases.

High quality confirmed

A durable and reliable compressor is an effect of a perfect design, but also high of quality materials and components. Airpol, using its extensive experience in compressor production gained over 60 years in the pneumatic industry, has developed solutions that combine the highest quality with low operating costs.

The applied ASU screw compression stage with optimised rotor profile, completely designed, manufactured and tested at Airpol, guarantees reliability and high compressor performance throughout its entire service life. Appropriately oversized bearings and low tolerance applied during the entire production process of screw compression stages ensure their durability and long service life. The electric motor with IE3 efficiency class is directly coupled to the screw stage via a flexible coupling. The result is loss-free energy transfer from the electric motor to the screw stage, reduced maintenance costs and high uptime. Inspection at every stage of the compressor production, the high quality components used ensure that the Airpol screw compressor is an investment for years.

MS-286 and MS-686 AIRPOL POWER CONTROL intelligent microprocessor controllers compliant with cyber security standards

The MS-286 and MS-686 AIRPOL POWER CONTROL microprocessor controllers designed specifically for use with Airpol screw compressors provide efficient operation and safety of the entire system, as well as compressor operating parameters monitoring. Very easy to use and intuitive, offering wide range of options: operation modes choice, specific settings modification, current compressor parameter values monitoring, status of operation time counters, energy consumption and many more. Additionally, in Airpol PR screw compressors designed for pressures up to 10 bar, the Ultra Speed function activation enables the user to adjust pressure within the range of 6.5 – 10 bar and thus change compressor capacity. This is particularly beneficial in the case of temporary increased demand for compressed air.

The MS-286 and MS-686 controllers comply with cyber security standards, which provides compressor operation secure remote monitoring.

- Web server hosted from the Controller (no cloud), regardless of Internet access.

- No need to send data outside the LAN structure.

- Eliminate the risk of spying and cyber-attacks.