Typically, production processes use compressed air with a pressure of up to 10 bar. In such cases, compressor stations equipped with screw compressors and an appropriately selected compressed air treatment line supply the factory with compressed air and ensure continuity of production.

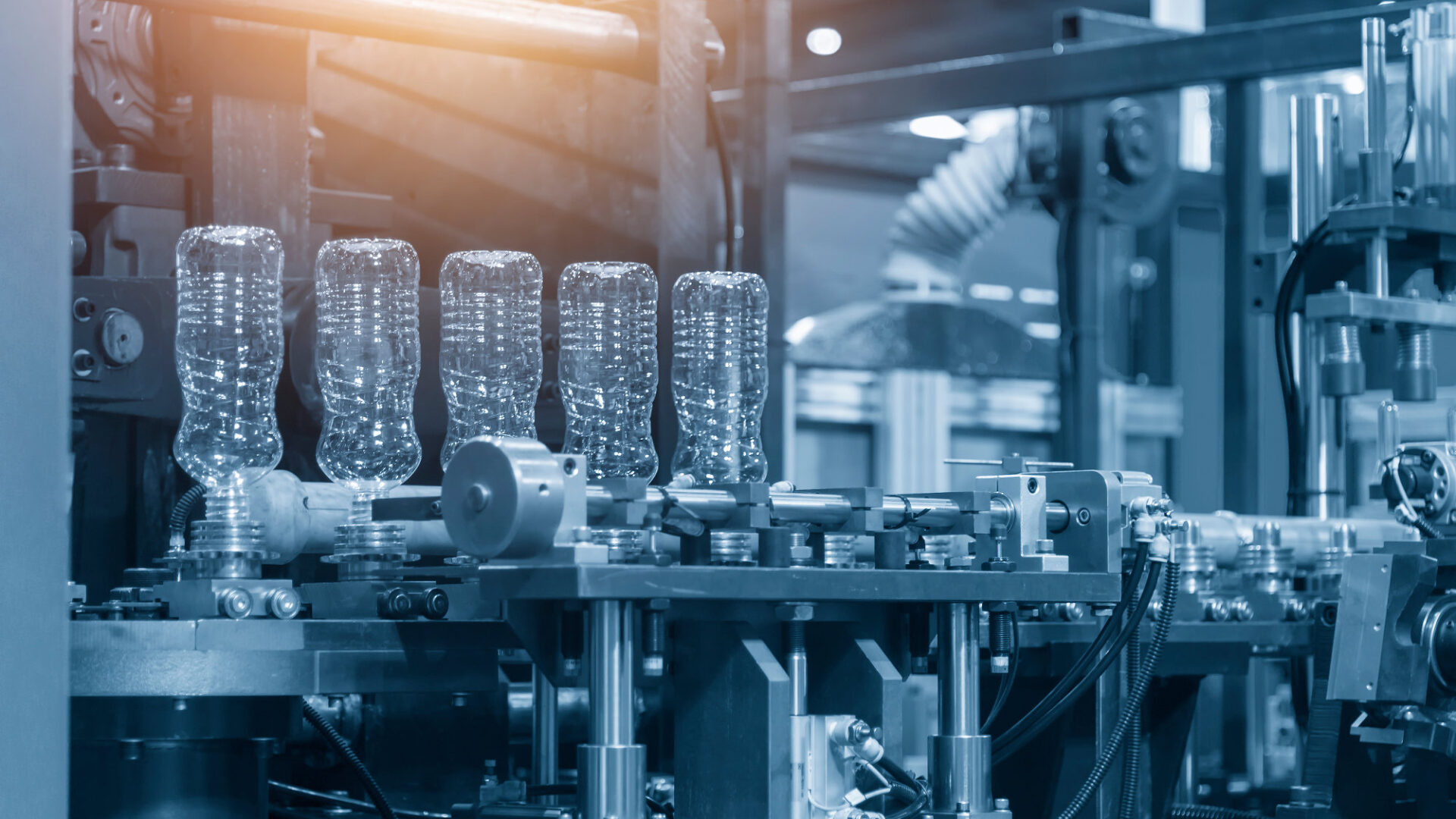

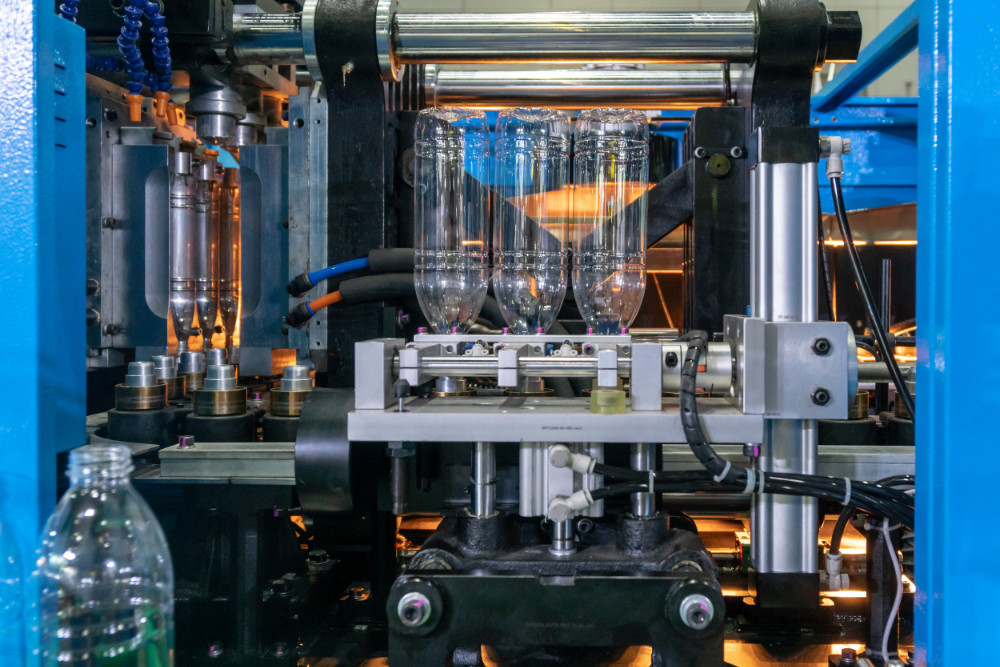

There are also applications for higher pressure compressed air, for example in the food, chemical, cosmetics and pharmaceutical industries, where PET bottles are widely used. The popularity of these packaging, versatility of applications, ease of personalization and a fully automated production process mean that companies producing lines for the production of pet bottles constantly modernise their machines, automating production by selling their products worldwide. In order to carry out the blowing process, blow moulding machines need compressed air with a maximum pressure of 40 bar. The requirements for compressed air depend on the technical parameters of the individual blow moulding machine – the maximum size and number of bottles that are or can be produced on the machine.