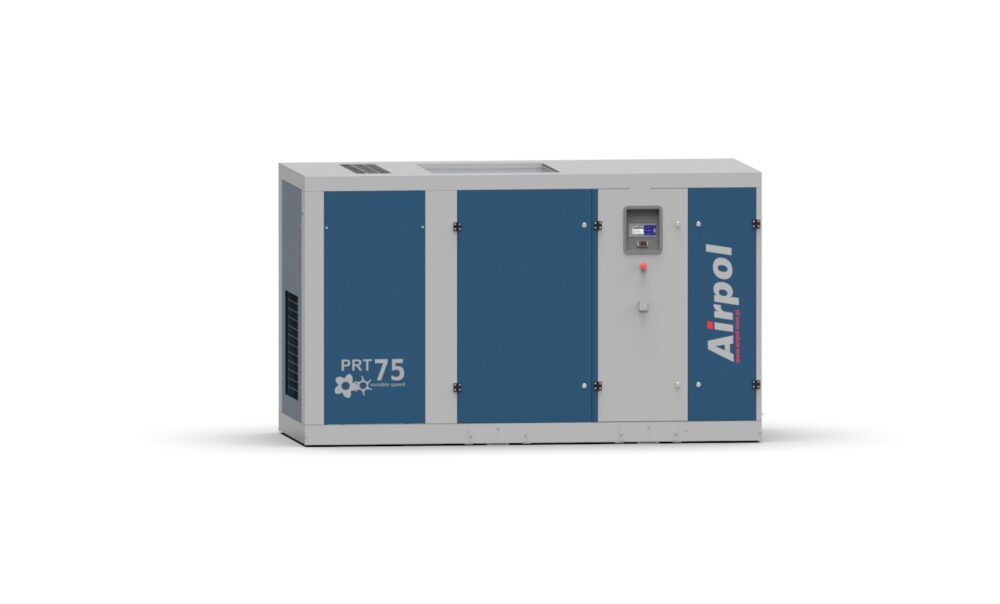

Airpol PRT screw compressors equipped with a frequency converter and a refrigerated air dryer use variable speed drive technology. Our engineers designed these compressors with improved energy efficiency to ensure an efficient, high class air system and at the same time enable users to reduce their energy bills. The special drive and intelligent control system used in Airpol PRT screw compressors controls the compressor speed, which results in:

- smooth regulation of compressor speed within the range from 20% to 100%,

- adjustment of compressor capacity to actual consumption of compressed air,

- energy savings up to 70% in comparison to compressors with traditional control.

When the demand for compressed air is low, the motor in a variable speed drive screw compressor will run at reduced speed. This will result in lower electricity consumption. The motor frequency of the variable speed compressor will automatically increase when the demand for compressed air increases. This adaptation of compressor operation has measurable benefits in the form of lower electricity costs and less wear on compressor components, which extends compressor service life and reduces maintenance costs.

- constant network pressure at a preset value

The frequency converter control system tries to maintain the compressor motor rotation speed so that there is a constant pressure in the compressed air system at a preset value. When the network pressure decreases the inverter increases the rotational speed of the electric motor, which increases the capacity of the compressor, whereas when the pressure increases the rotational speed of the motor decreases.

High quality dried and filtered compressed air

The integrated air treatment ensures high quality process air and thus corrosion protection for the pneumatic equipment and the entire system. At the customer’s special request, we are ready to modify the configuration of filters to obtain air parameters that meet the specific requirements of the technological process.

The refrigerated air dryer and two compressed air filters are located in one casing together with the entire compressor unit. This eliminates the need for additional working space and the expense of installing a treatment system, which includes:

- Pre-filter for high dust storage capacity (removes 99% of solid and liquid particles larger than 3 μm)

- Refrigeration dryer – removes moisture from the compressed air up to the required dew point of +3ºC.

- Fine filter – cartridge made of multilayer dense microfibre (removes 99% of solid particles larger than 1 μm and ensures that the residual oil content behind the filter does not exceed 0.1 mg/m3 ).

MS-686 AIRPOL POWER CONTROL intelligent microprocessor controller compliant with cyber security standards

The MS-686 AIRPOL POWER CONTROL microprocessor controllers designed specifically for use with Airpol screw compressors provide efficient operation and safety of the entire system, as well as compressor operating parameters monitoring. Very easy to use and intuitive, offering wide range of options: operation modes choice, various settings modification, current compressor parameter values monitoring, status of operation time counters, energy consumption and many more.

What especially stands out the MS-686 controller from other controllers on the market is the security of compressor operation remote monitoring.

- Web server hosted from the Controller (no cloud), regardless of Internet access.

- No need to send data outside the LAN structure.

- Eliminate the risk of spying and cyber-attacks.

High quality

Airpol PRT screw compressors combine durability and reliability resulting from excellent design and high quality components. Airpol, using its extensive experience in compressor production gained over 60 years in the pneumatic industry, has developed solutions that combine the highest quality with low operating costs.

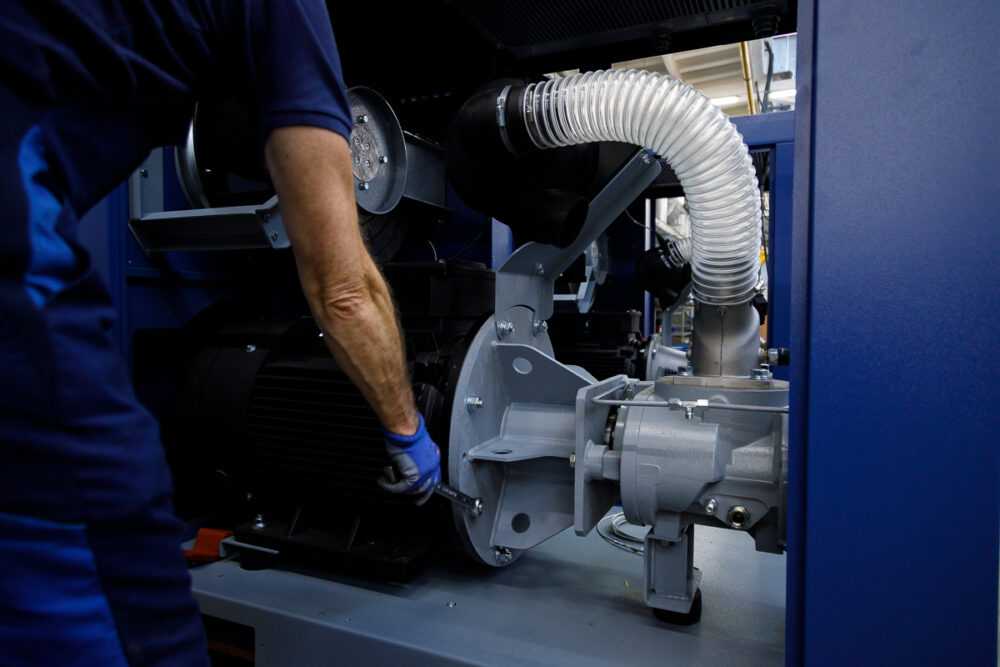

The applied ASU screw compression stage with optimised rotor profile, completely designed, manufactured and tested at Airpol, guarantees reliability and high compressor performance throughout its entire service life. Appropriately oversized bearings and adopted low tolerance parameters that we use during the whole process of screw stage production ensure their durability, long service life and high quality.

The electric motor is directly coupled to the screw stage via a flexible coupling. that provides a loss-free energy transfer from the electric motor to the screw compression stage, reduced maintenance costs and high uptime.

A high-performance radial fan with higher compression ensures effective cooling throughout the entire life of the compressor. The high compression ensures an adequate and uniform flow of the ambient air drawn in through the cooler, even in the case of significant contamination. The fan is driven by a low-speed motor, which significantly reduces the sound emission level of the entire compressor.